Product/Packaging Design & Manufacturing

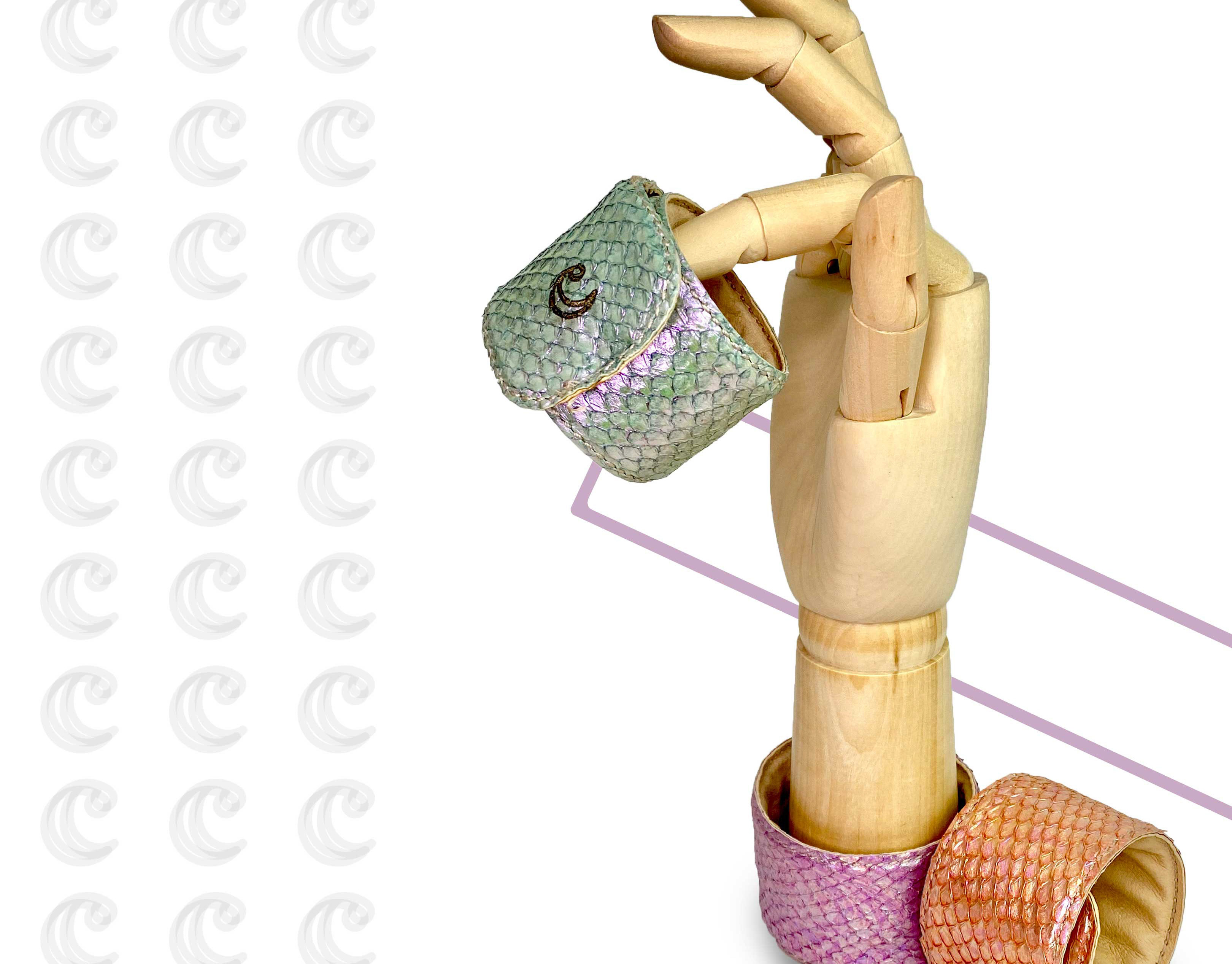

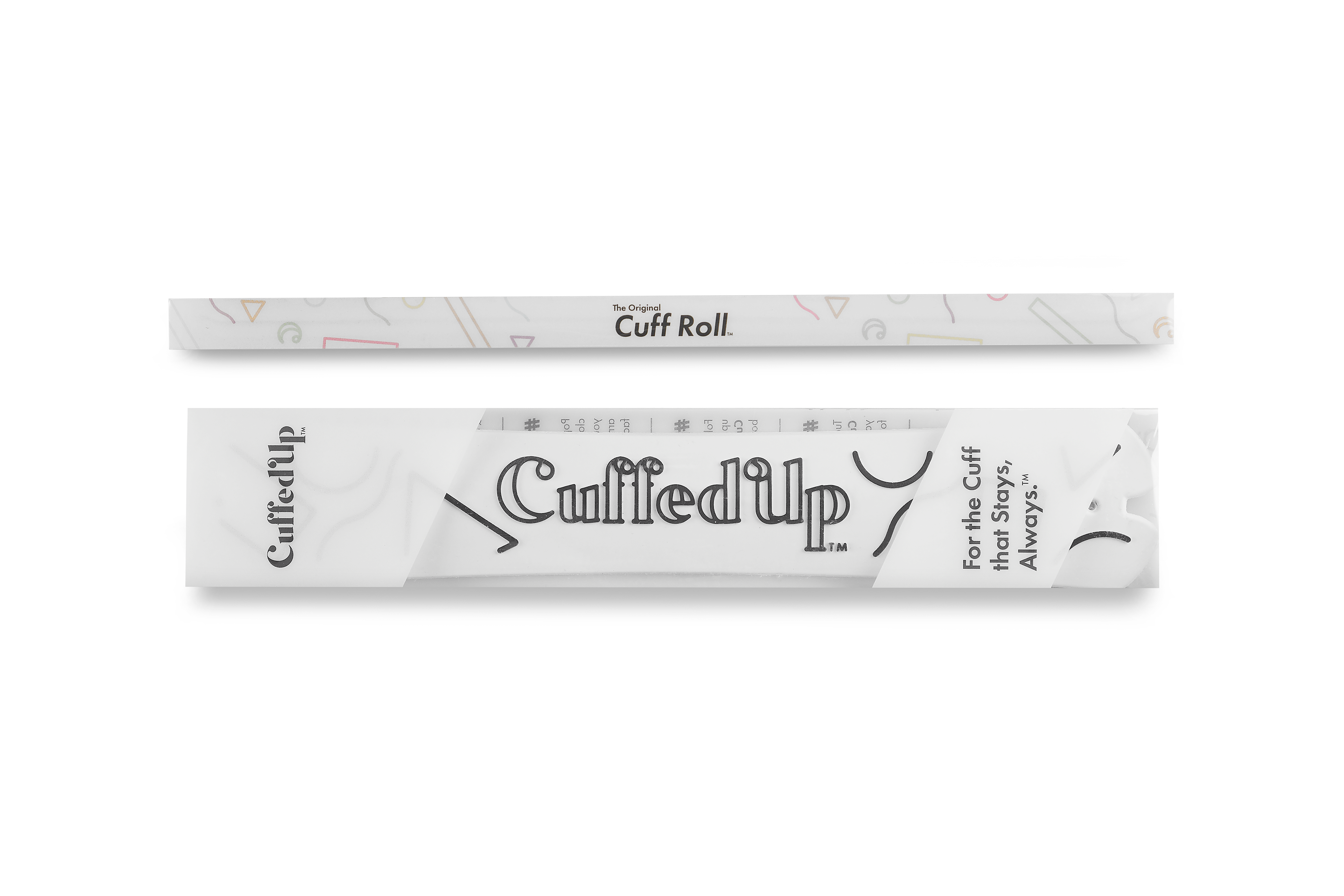

I designed the Cuff Roll™ by CuffedUp™, a patent-pending accessory that rolls and styles sleeves. Designing this product took months of R&D to measure & find an average forearm size, source materials, experiment with different solutions, and find a cost-effective way to produce it.

My challenge was to design a single product that fits 80% of people that is undetectable under thin fabrics, like silk, but strong enough to hold thick fabrics like denim. But that was the easy part! The biggest challenge by far was to create something that a user wouldn't notice on their arm and didn't squeeze. I'm happy to say all of these criteria were met in a short, 3 month ideation to manufacturing timeline.

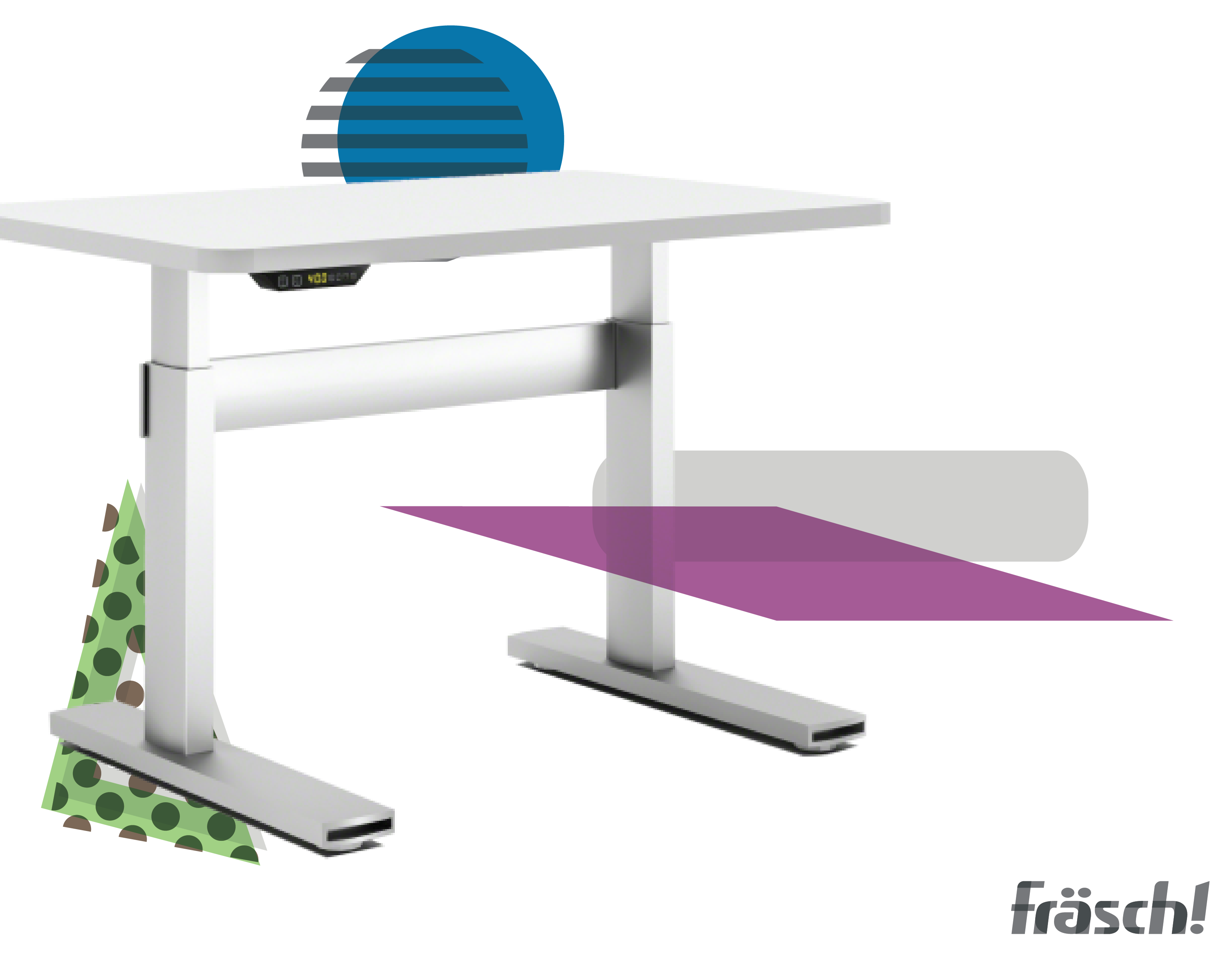

Rapid Prototyping & Product Dev.

At first, we thought a slap bracelet would work. But it popped off our arms when we tucked fabric underneath it. So we needed to figure out why. I started with materials like duct tape, tape measurers, and liquid silicone to get early versions done quickly on a tight budget. From there, I found a manufacturer overseas who was willing to help us prototype a few versions from there. Settling on the final product below.

Worked with Manufacturer: I communicated requirements to our manufacturer overseas. This was a challenge but ultimately I was able to build a great relationship with them- which made the process easier and cheaper for us!

Troubleshot Quality Issues: I looked at products off the production line and helped figure out how we could improve the results without compromising the design.

Product Dissection

The best design is intentional design. I embedded the brand into the product itself using the elements on the bottom. CuffedUp needed a textured bottom to grip a shirt, and this was a great opportunity to brand the product.

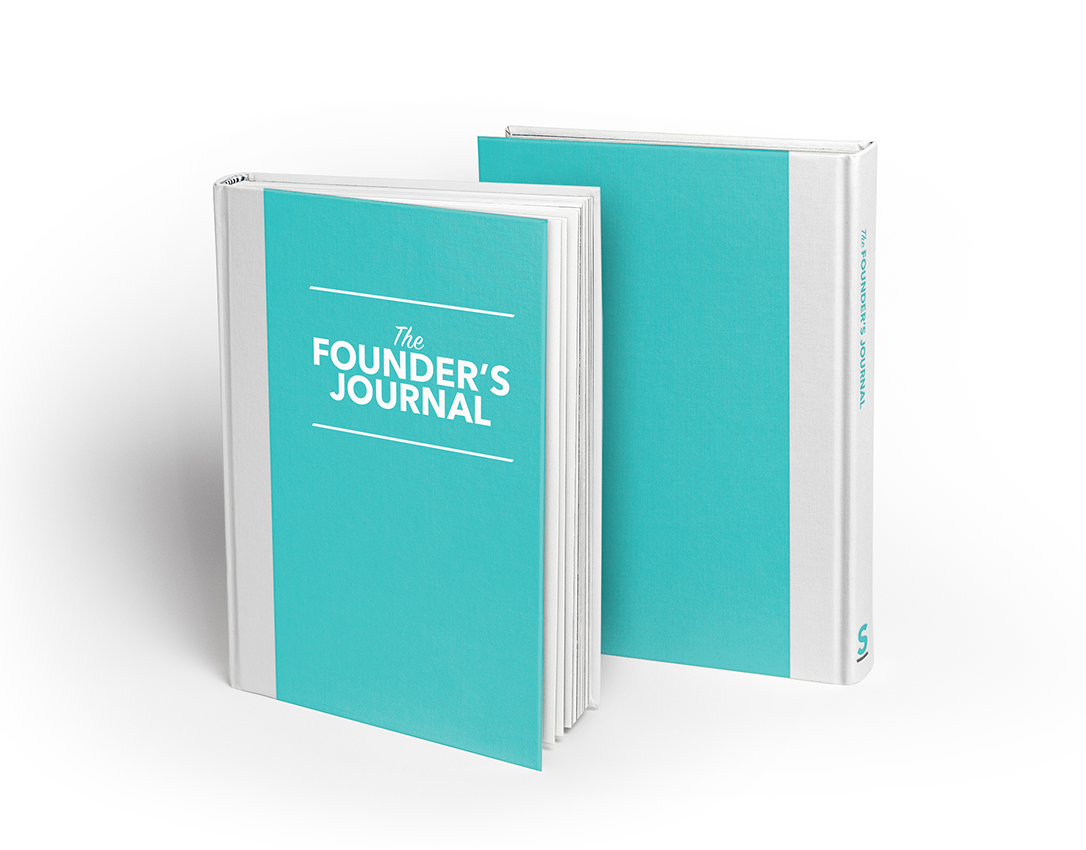

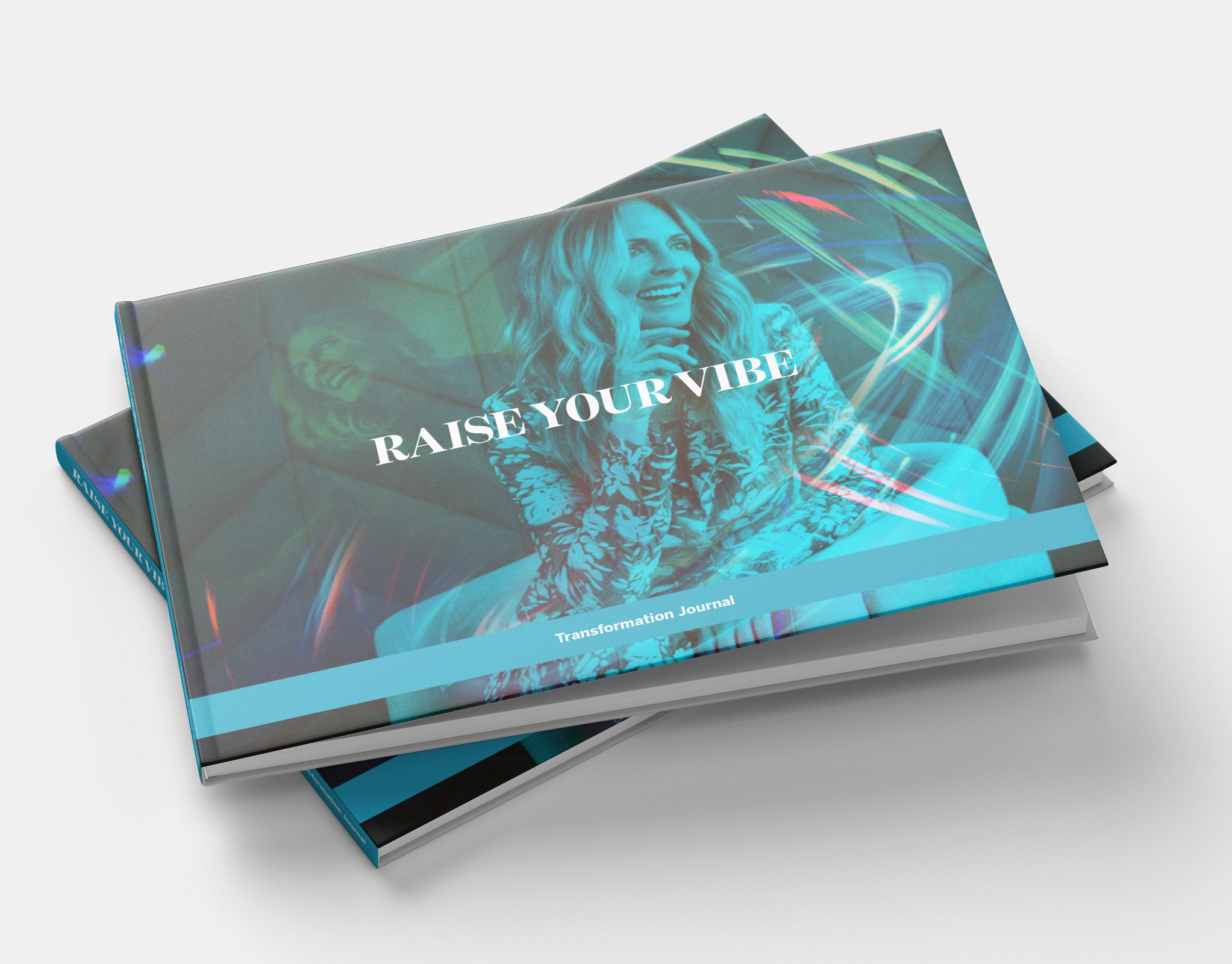

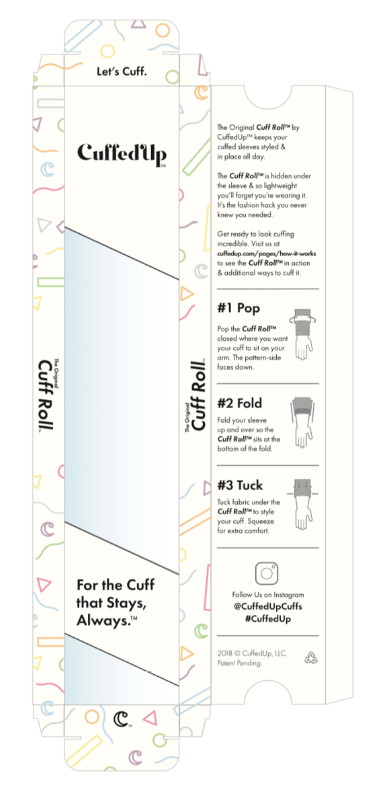

Packaging Design

I created packaging that matched the brand's position as a premium product. I also included simple instructions on the back.

Product Staging